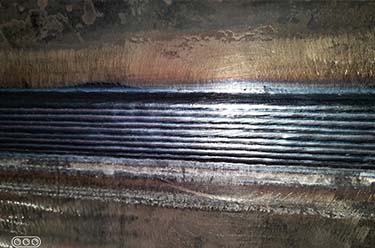

Automatic girth welding

BYGGING submerged arc AUTOMATIC GIRTH WELDING (AGW) machine for SINGLE SIDE WELDING suitable for horizontal welding of tanks built “TOP-DOWN”

Salient Features:

.- Make of Power Source & Wire Feeder - Lincoln Electric, USA.

- Weatherproof Electrical cabinet.

- Robust DC motor for tractor movement.

- Auto flux recovery unit.

- Fine adjustable manual cross slide for vertical & horizontal adjustment.

- Weld head slide assembly.

- Auto sensor for wire feeder speed.

- Flux stored in Flux Recovery Unit as well as in Flux discharge hopper.

- View glass in flux hopper & in Flux Recovery Unit

- Same Power Source can be used for root welds and for FCAW / MIG / SMAW vertical welds.

- Two or more FCAW / MIG / SMAW welding heads can be used using one Power Source (by using Multiweld 350) which increases vertical welding productivity by more than double.

- Same mechanism can be used for Arc gouging.

- Ambient temperature range at which the machine can work : -5 to + 65 deg C.

- Machine is compact, light weight & can be handled without the need for a large crane.

Bygging AGW's Productivity is equivalent to that of 6 welders.

Technical Specification:

.| Welding plate width | : | For first / top shell - Min. 800mm For subsequent shells - No restriction. |

| Tank diameter | : | Suitable for tanks more than 8 mtr in diameter. |

| Welding current | : | From 250 Amps Upto 1000 Amps at 100% duty cycle. |

| Output Voltage | : | 44V |

| Welding Speed | : | 250 mm to 700 mm/min |

| Idle Travel Speed | : | Upto 1000 mm per minute. |

| Wire diameter | : | 2.4 / 3.2 mm / 4 mm |

| Weight of Welding head | : | 216 kgs (approx.) without flux & wire spool. |