Tank Jacking Equipment for API 650 Tanks – Trusted Supplier & Manufacturer by Bygging

Bygging is a globally trusted supplier and manufacturer of tank jacking equipment for API 650 tanks, widely used in oil & gas and petrochemical storage projects. Our hydraulic jacking solutions simplify tank erection, reduce construction risk, and improve project timelines while fully complying with international standards.

Tank Jacking Equipment for API 650 Tanks

Tank jacking equipment for API 650 tanks is a hydraulic lifting system used to raise large welded steel tanks in a controlled and synchronised manner. Instead of relying on heavy cranes or extensive scaffolding, hydraulic jacks are positioned around the tank shell to help lift the tank shell, enabling the build or repair of the storage tank.

API 650 tanks are widely used for storing crude oil, petroleum products and chemicals. These tanks are large, heavy, and require efficient and controlled erection methods. Tank jacking has become the preferred technique because it improves safety, ensures accuracy, and reduces overall construction time.

Bygging designs its jacking systems specifically for API 650 compliance, ensuring stability, uniform load distribution, and controlled lifting throughout the process.

How the Tank Jacking Method Works

-

Initial Setup:

The required number of hydraulic jacks are placed equidistantly around the circumference of the tank. All the jacks are connected to a central powerpack using hose lines in a way that an oil cushion is formed between all jacks. The tank is more or less lifted uniformly in increments of 100 mm. -

Controlled Lifting:

The jacks lift the tank shell in small increments, each stroke being 100 mm. This controlled movement prevents distortion of the shell plates. -

Ground-Level Fabrication:

As the tank is lifted, new shell plates are added below and welded. Since erection, fit-up and welding is carried out at near ground level. This ensures a good fit-up and weld quality and makes inspection easier. -

Repeated Cycles:

The lift-and-weld cycle continues until the full height of the API 650 tank shell is achieved. -

Final Lowering & Completion:

The lowermost shell course is directly placed on the tank annular plate and then the lifted part of the tank is lowered down to sit on this lower-most shell course, and this last circumferential joint is welded. With this the shell erection is complete and the jacking equipment is dismantled and removed from the tank.

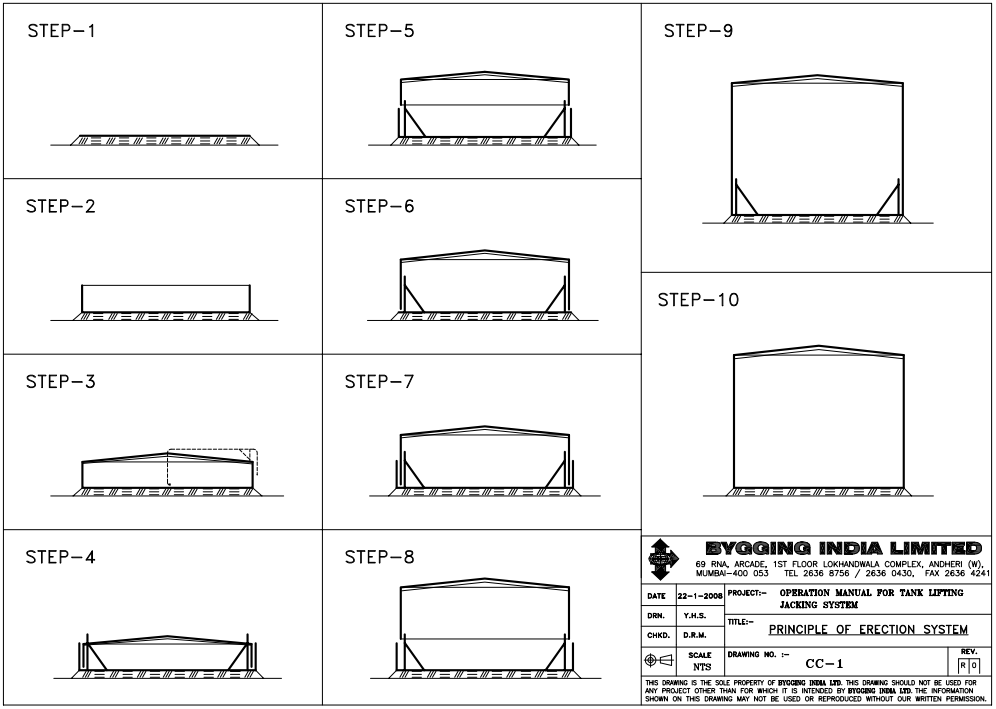

Steps to install API 650 Tanks

Why Tank Jacking Is Preferred Over Conventional Methods

Compared to crane-based or scaffold-heavy construction, tank jacking offers clear advantages:

- Improved Safety: Most work is done at ground level, reducing fall risks.

- Higher Welding Quality: Better access and visibility during fabrication.

- Faster Construction: Reduced downtime and smoother workflows.

- Lower Project Cost: Minimal crane use, less scaffolding and very little manhours required.

- Better Load Control: Uniform lifting prevents shell plate deformation.

For large API 650 tanks, these advantages make hydraulic jacking the most efficient and trusted erection method.

Bygging – Supplier & Manufacturer of Tank Jacking Equipment

Bygging is not just an equipment provider; we provide an end to end service. Right from providing method statements and risk analyses to providing on-site technical assistance.

As a leading supplier and manufacturer of tank jacking equipment for API 650 tanks, we focus on safety, durability, and ease of operation.

What Sets Bygging Apart

-

Technically Robust Hydraulic Jack Design:

Built for fail-safe operation and long service life -

API 650-Focused Engineering:

Systems designed to meet global tank construction standards -

Customised Design:

Each order is serviced separately and the jacking equipment is customised based on tank dimensions -

Global Project Experience:

Trusted in oil terminals, refineries, and industrial liquid storage plants worldwide -

Technical Support & Training:

Assistance during planning, installation, and operation

Our systems are engineered to perform reliably even under challenging site conditions, making Bygging a preferred choice for tank contractors and builders.

Applications of Bygging Tank Jacking Systems

Bygging’s tank jacking equipment for API 650 tanks is used across a wide range of applications:

- New API 650 storage tank construction

- Tank bottom plate replacement and foundation repair

- Tank height expansion by adding shell courses

- Tank maintenance projects

- Dismantling or relocation of existing tanks

Whether the project involves a greenfield tank farm or upgrading an existing facility, Bygging provides the right hydraulic jacking equipment.

Quality, Safety, and Reliability

Every Bygging system undergoes strict quality checks before delivery. Our focus is on:

- Fail-proof operation

- High-quality hydraulic equipment

- Smooth and synchronized lifting without damaging the shell plate

- Long-term operational reliability and longevity of the tank jacks

Safety is built into the design, ensuring controlled lifting and stable tank support throughout the erection process.

Why Choose Bygging as Your Tank Jacking Partner?

When you choose Bygging, you gain more than just equipment:

- Proven manufacturer with industry experience

- Reliable supply for domestic and international projects

- Custom configurations based on tank size and load

- Responsive after-sales and technical support

- Longevity and durability of equipment

This commitment makes Bygging a trusted name in tank jacking equipment for API 650 tanks across global markets.

Book Now – Request a Quotation from Bygging

Planning an API 650 tank project? Bygging is ready to support you with the right tank jacking solution.

- Get expert guidance

- Receive competitive pricing

- Ensure safe and efficient tank erection

👉 Book now or request a quotation today through:

https://www.jackingsystem.com/

Our technical team will help you select the most suitable jacking system for your project requirements.

Frequently Asked Questions (FAQs)

Q1. Is Bygging’s tank jacking equipment suitable for all API 650 tanks?

Yes, Bygging systems are designed to handle a wide range of API 650 tank sizes and capacities.

Q2. Can the same jacking system be used for repair projects?

Absolutely. Our equipment is widely used for tank bottom replacement, repairs, and upgrades.

Q3. Does Bygging provide technical support during projects?

Yes. We offer technical guidance, documentation, and operational support when required.

Q4. How do I get pricing for tank jacking equipment?

You can request a quotation directly from Bygging via our website for fast and accurate pricing.